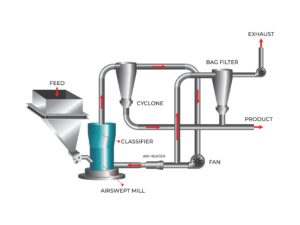

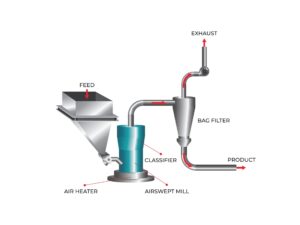

If you find yourself in the market as a first-time buyer of an airswept mill, or even if you’re an airswept mill ‘veteran’, chances are you will find yourself making the critical decision of choosing between a Single-Pass Airswept Mill System vs. a Recycled Air System. There are certainly projects where the specifications of the process dictate a clear-cut choice of one system over the other, but most fall into a gray area where the best solution can only be determined through a complete understanding of the process from raw material to end product.

Airswept mills are diverse machines engineered to handle a wide range of processes, materials, and specifications, and in a perfect world you would simply feed raw material in one end and collect the pulverized material out the other end as finished product. But in the real world, a multitude of factors require airswept mills to be supported by ancillary equipment configured as a system to regulate the milling process for maximum, long-term efficiencies in product output. These factors start with an understanding of the end-product’s specifications, followed by an understanding of the physical properties of the raw material such as moisture level and temperature, and ultimately the economics of up-front costs vs. ongoing maintenance.

Whenever sourcing an airswept mill, it is critical that both single-pass and recycled air systems be quoted. Furthermore, we caution buyers to look beyond cost, vendor location, or even yield rates. As with most engineered systems there are critical short term and long-term cost/benefits to consider that factor into and may even dictate which system is the correct choice.

- Fuel: How much heat (fuel/energy) will be required to maintain proper moisture levels?

- Filtration: What size filter is required along with maintenance cost of filter maintenance?

- Grain size (end product): How aggressively will the materials processed in the system wear on the machinery itself?

The choice between a single-pass vs. a recycled airswept mill system will directly affect the overall return on capital investment, so it is certainly a decision that requires careful consideration. Yet, most people do not have the information needed to clearly make the decision on their own. The Sales Engineers at Bradley Pulverizer work with all our clients to understand the specifications of your process with careful consideration to the costs/benefits of both start-up and long-term maintenance costs. We clearly demonstrate the tradeoffs of each system from a long term economic, production, and maintenance standpoint.

Bradley Pulverizer is unique in the market in that we manufacture both single-pass and recycled air systems and welcome customizations, which allows us to be more versatile, flexible, and adaptable in engineering the right system for your application. We have encountered many low cost, ‘stock’ systems in operation that require so many modifications it is difficult to discern the OEM. Conversely, partnering with an OEM like Bradley Pulverizer ensures that the system meets your specific requirements, minimizes vendors, and optimizes ongoing maintenance.

Contact Us to find out which Airswept Mill System is right for your next materials processing application.

(US) 855-670-8777 | (International) +44 1322-559-106