Stainless Steel Windsifter Air Classifiers

Efficient Air Classification for Hygienic / Specialized Applications

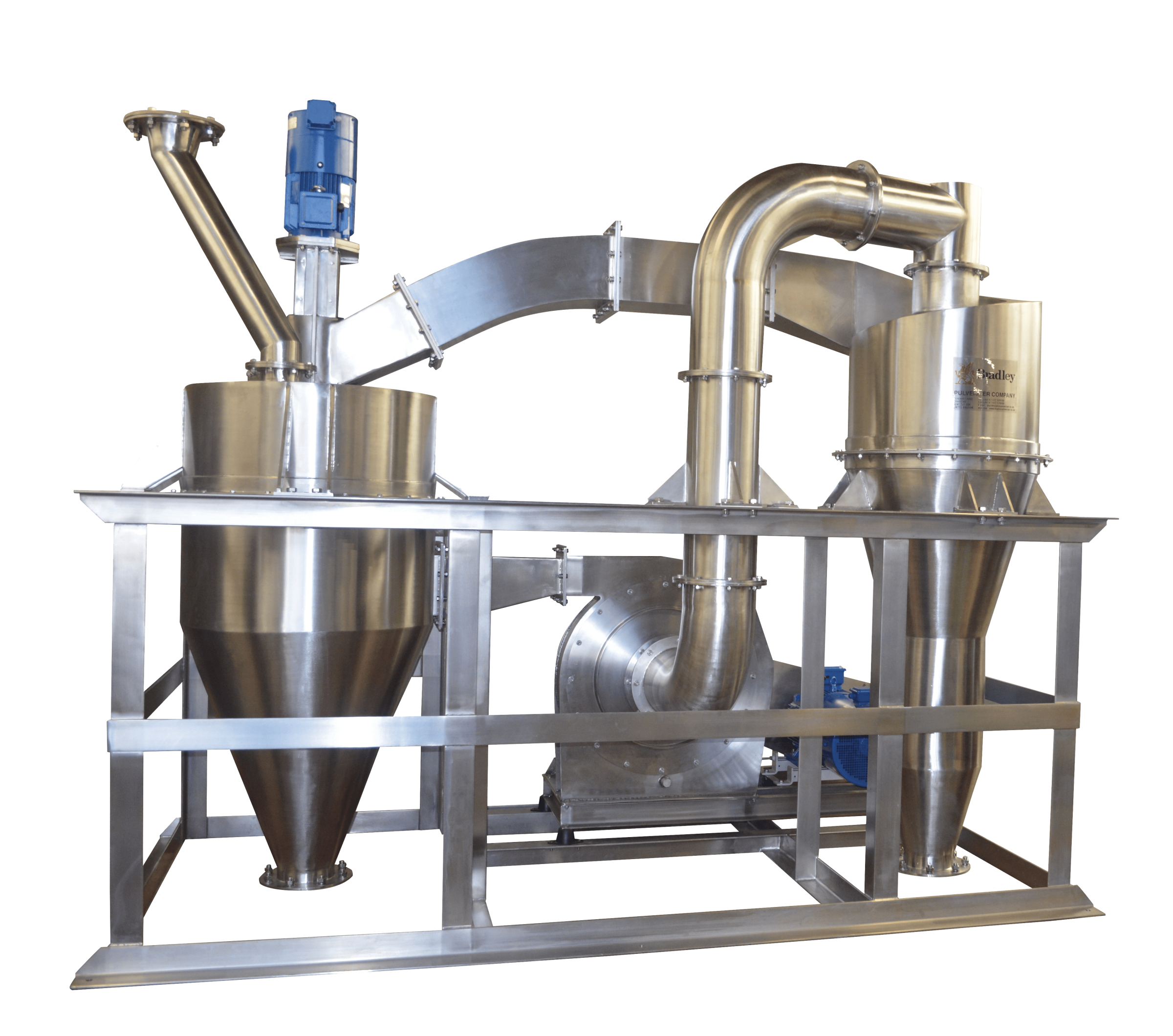

The innovative NEW Bradley Windsifter SS offers the same reliable air classification of coarse and fine particles – now for hygienic applications. Constructed of polished stainless steel throughout, the stand-alone Windsifter SS is skid mounted for easy installation and can be manufactured with a cyclone or hygienic filter.

Stainless Steel Construction

The Windsifter SS is manufactured with a standard specification of 0.8-RA internal and 1.2-RA external stainless steel. Higher quality polish or bead blast/brushed finish are available, if required. The polished surface provides a hygienic and easy to clean surface. With food grade seals and grease, it can be designed to comply with required local standards.

Stainless steel is also non-sparking for lower explosion/combustion risk. The Windsifter SS to be easily purged with an inert gas, such as CO2 or Nitrogen, to lower explosion risk and/or to prevent oxidation of material being processed.

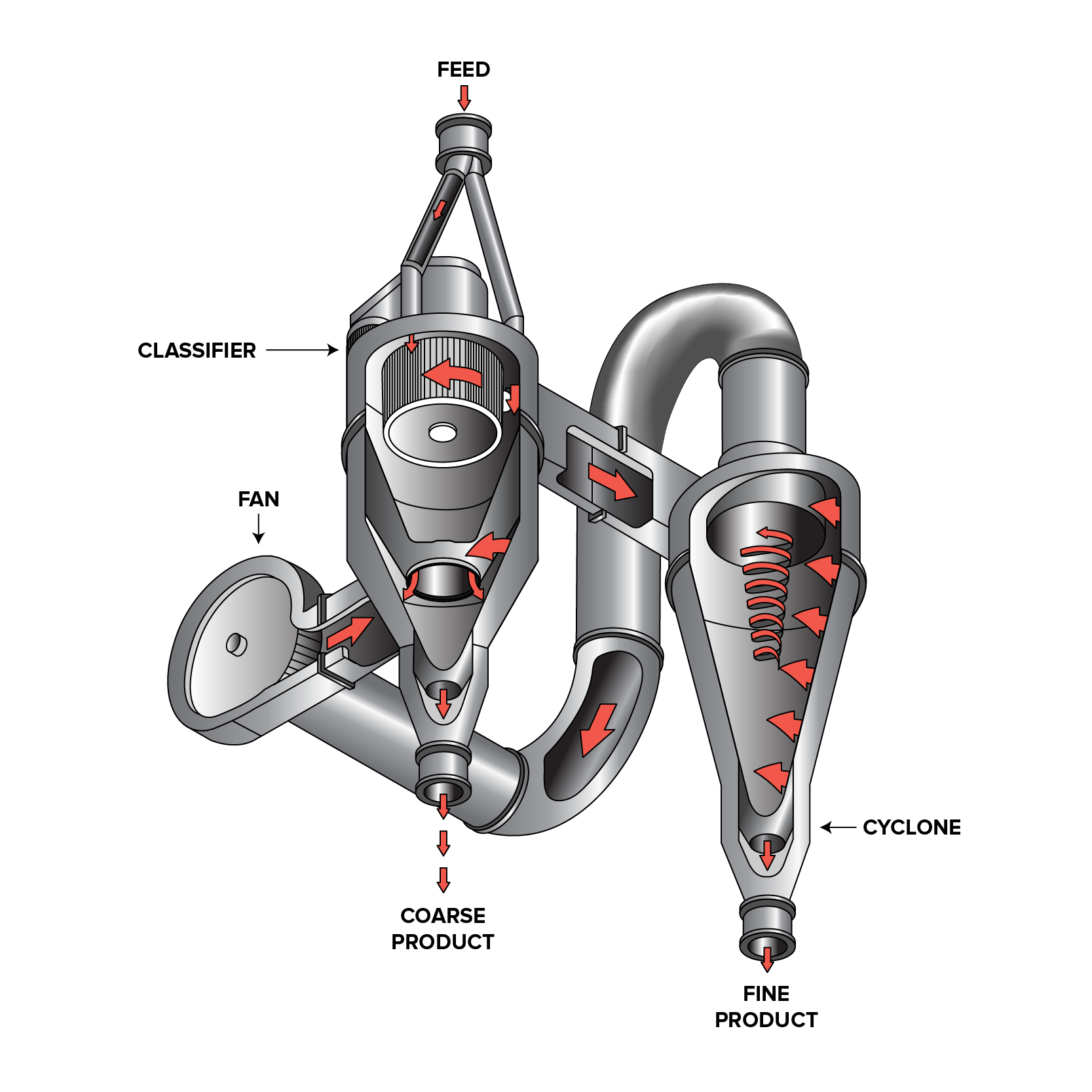

How It Works

The Vertical Blade Classifier (VBC) technology incorporated into the Bradley Stainless Steel Windsifter Air Classifier utilizes vertical oriented blades and the separator rotor to create a vortex, spinning the air and throwing the coarse particles out to the sides, where they fall for bagging. Fine particles are carried through the separator rotor and up to the cyclone or bag filter.

Performance Features

- Capacities up to 10TPH

- Particle sizes within a range of 5 to 250 microns

- Instant size control through adjustment of separator rotor speed

- Easy access hatches in key places.

- Optional stainless steel finishes available

- Special application rotor designs available

Specialized Dynamic Classification

| MATERIAL |

|---|

| Metal Powders |

| Food Ingredients |

| Dyes & Pigments |

| Carbon Powders |

| Mineral Powders |

| Battery Materials |

| Specialty Powders |

| APPLICATIONS |

|---|

| Hygienic classification |

| Low Contamination Processing |

| Non-Sparking Applications |

| High Corrosion Applications |

Specifications

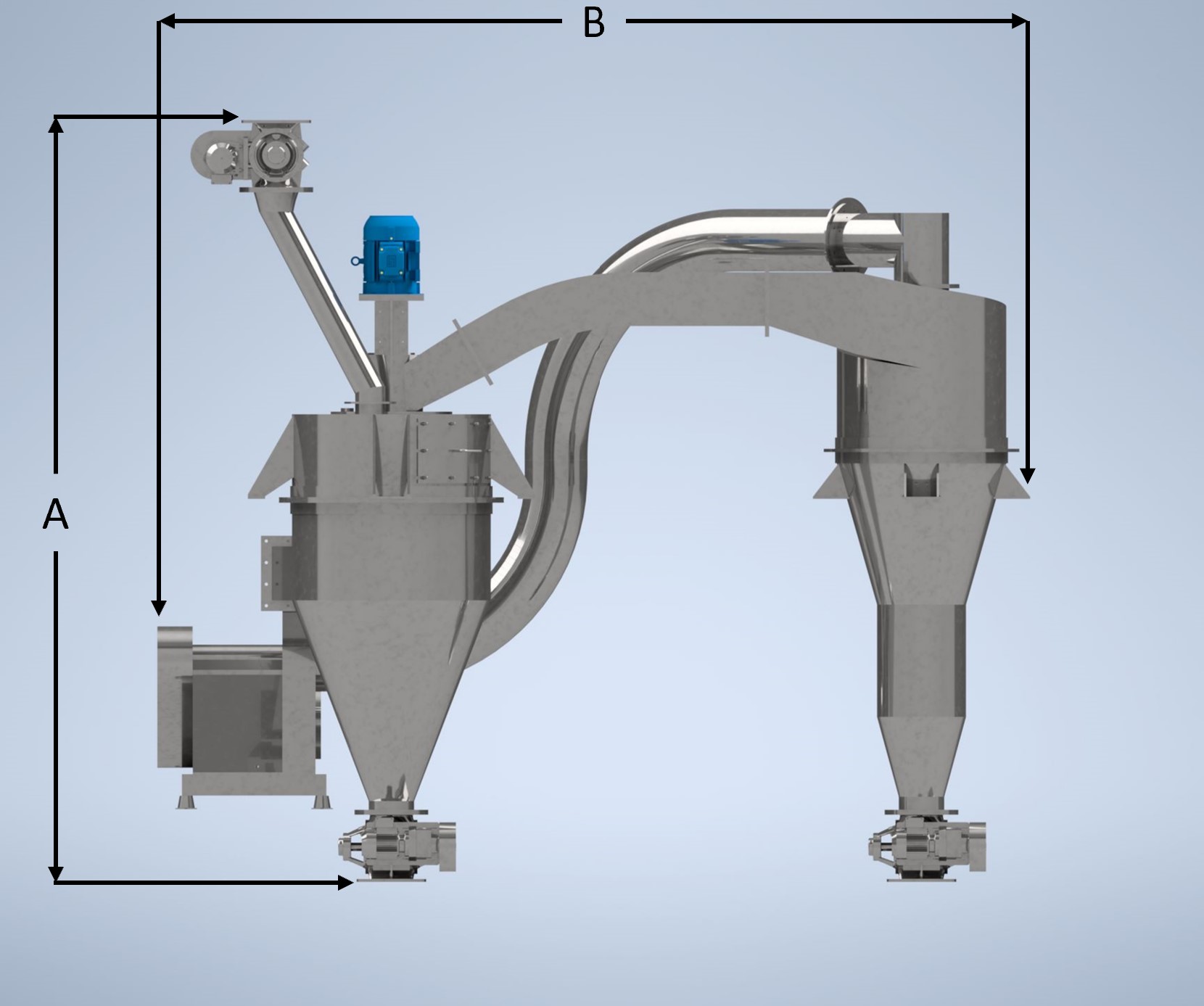

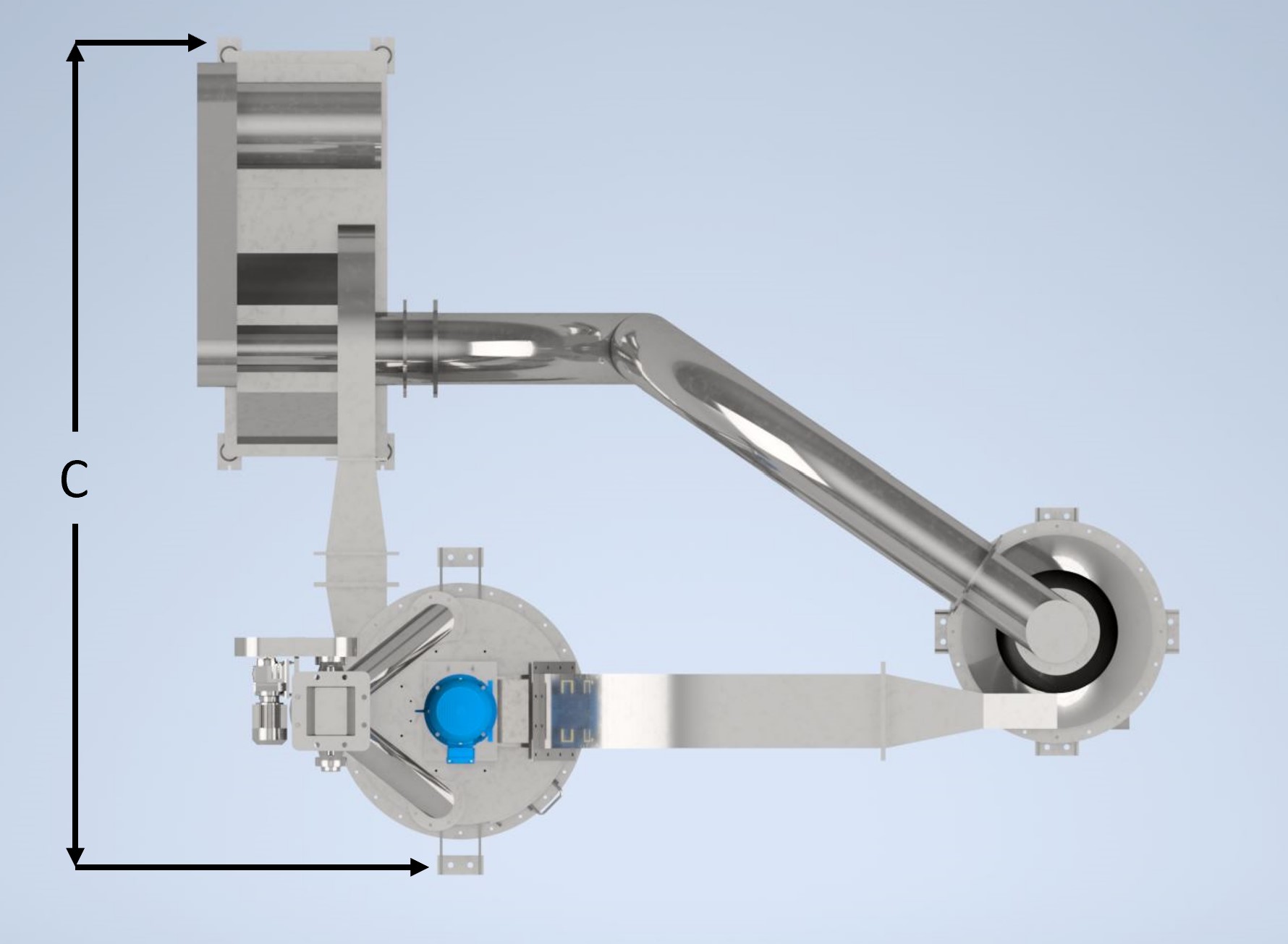

| TYPICAL WINDSIFTER DETAILS | |||||

|---|---|---|---|---|---|

| UNIT SIZE | Dimensions | Power | |||

| A | B | C | ROTOR | FAN | |

| MS LAB | 2.13 m 7 ft |

1.52 m 5 ft |

1.52 m 5 ft |

.75 kW 1 HP |

1.49 kW 2 HP |

| MS1 | 3.04 m 10 ft |

3.04 m 10 ft |

2.13 m 7 ft |

2.98 kW 4 HP |

5.22 kW 7 HP |

| MS5 | 3.04 m 10 ft |

3.96 m 13 ft |

3.04 m 10 ft |

7.46 kW 10 HP |

14.9 kW 20 HP |

| MS10 | 3.96 m 13 ft |

4.88 m 16 ft |

3.96 m 13 ft |

11.19kW 15HP |

22.37 kW 30 HP |