Optimize Your Acidulation Process with Bradley Mixers

Key Factors in Mixer Selection

Selecting the correct mixer is critical for optimal acidulation process operation and control. As the heart of the acidulation process, the right mixer ensures proper reaction rates, product quality, and operational efficiency. The wrong mixer selection can lead to suboptimal mixing, low reaction rates, and compromised product quality.

The choice of an Acidulation Process Mixer depends on several factors:

- Type of superphosphate being produced

- Quality of phosphate rock and acid

- Variability in raw materials and throughput

- Process conditions and operational flexibility

Low-reactive phosphate rocks pose unique challenges that demand specialized mixer designs. These can include tailored paddle configurations, precision acid/rock nozzles, and customized materials of construction.

At Bradley Pulverizer, we conduct laboratory testing to determine the optimum mixer design and materials best suited for your process, whether producing SSP, TSP, or other acidic salts. We also accommodate special applications, such as incorporating liquid sulfur through heated pipelines and nozzles to produce sulfur-rich products.

Acidulation Mixer Types

The table below provides a comparative overview of available acidulation mixers, their applications, advantages, disadvantages, and adjustability.

| Mixer Type | Product | Advantages | Disadvantages | Adjustability |

| Horizontal Paddle – Broadfield Mixer | SSP, TSP | Works with all phosphate rock types and acid strengths, flexible process adjustments | Large size | Yes (Mixing time, Mixing intensity) |

| Cone Mixer | Reactive phosphates | Simple design, low maintenance, no moving parts | No adjustment for throughput or raw material variations | No |

| Vertical Paddle Mixer | Active phosphates | Can accommodate lower acid strengths than a cone mixer, compact, flexible, low cost | Short residence time | Yes, but limited adjustments |

| Twin Shaft Mixer | Various applications | Commonly used for DCP with a cone mixer as a pre mixer | Complex design | Yes |

| Drum Mixer | High-grade phosphates | 100% mixing, adjustable residence time | Dependent on consistent feed rates and quality | Yes, but limited adjustments |

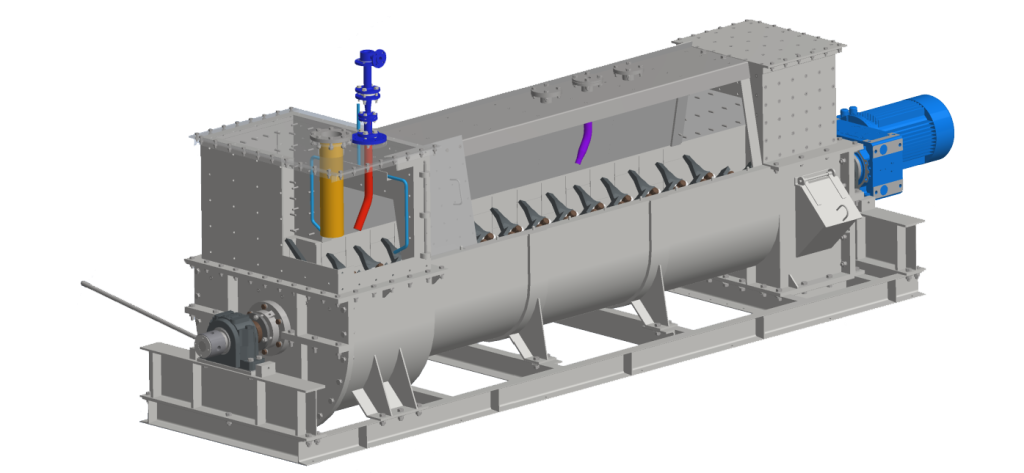

Broadfield Horizontal Paddle Mixer

The Broadfield horizontal paddle mixer is a versatile and reliable solution for all phosphate rock types and acid strengths. It allows for independent adjustment of mixing time and intensity, ensuring optimal processing.

Key Features:

- Lead lined carbon steel shaft with acid-resistant bronze bushings for gland areas

- Long-life paddles (NI Resist, NI Hard, or HMWPE Grade 500 plastic)

- Acid-resistant Carblox brick-lined mixer trough, capable of handling temperatures up to 180°C

- PTFE acid inlet piping with static acid mixer for durability

- Water curtain for dust suppression

- Optional adjustable weir plate for flow control

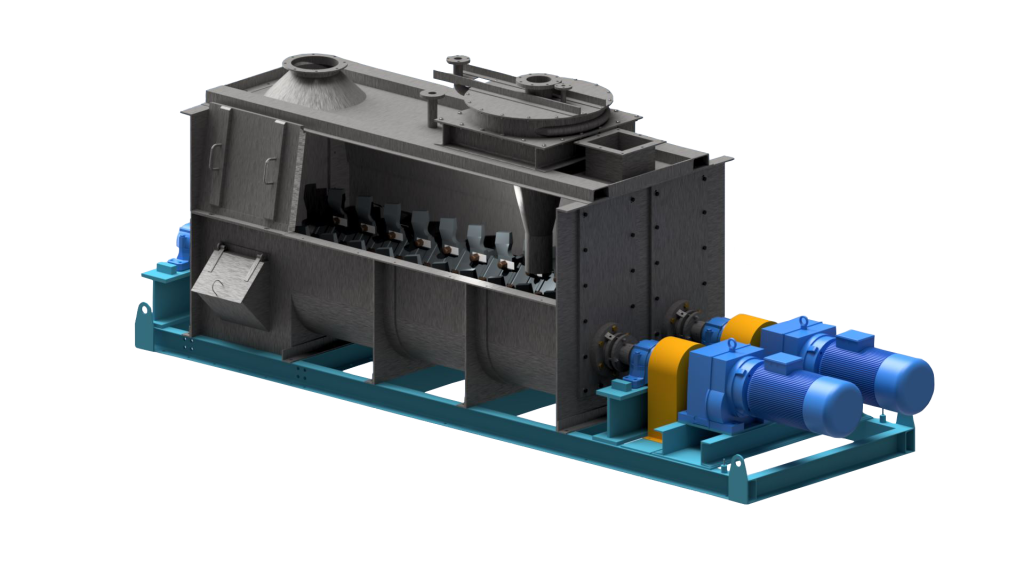

Twin Shaft Broadfield Mixer

This mixer is designed for high-performance acidulation mixing, offering superior control over residence time and material flow.

Key Features:

- 316L stainless steel construction for corrosion resistance

- Dual rotors with lead lined shaft for optimal mixing

- Acid-resistant paddles

- Adjustable retarder paddles to fine-tune residence time

- Integrated heavy-duty steel support frame

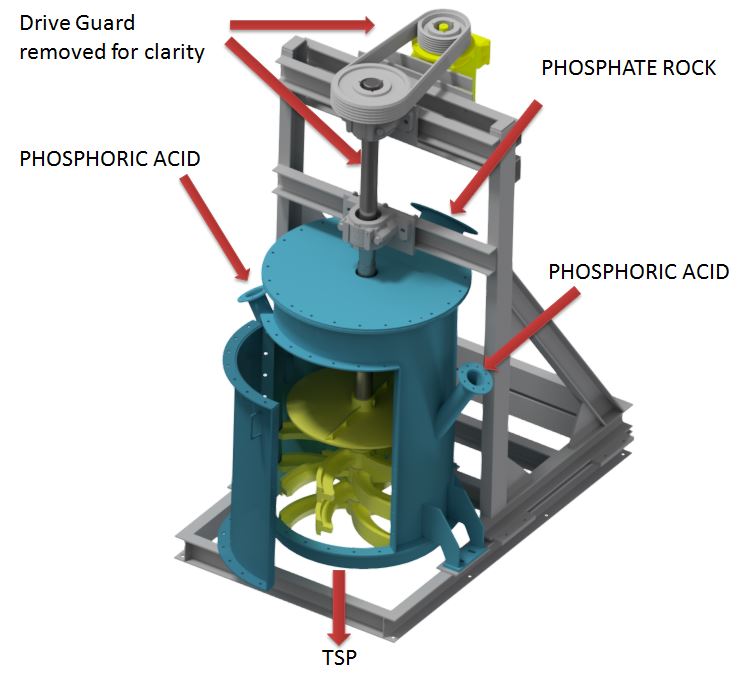

Turbine (Vertical) Mixer

A cost-effective and compact unit ideal for high reactive phosphates and weaker acid strengths.

Key Features:

- High speed mixing

- Simple opening for ease of cleaning

- Heavy-duty Supa Duplex mixer body with mild steel externals

- Spreader disc for even acid/rock distribution

- Belt-driven motor for easy speed adjustments

- Optional open-box or letterbox design

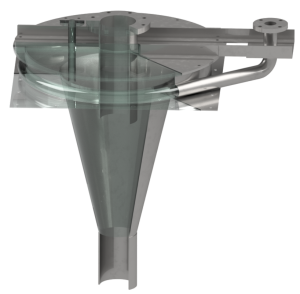

Cone Mixer

A simple and maintenance-free solution for reactive phosphates, ideal for fine-grind mixing applications.

A simple and maintenance-free solution for reactive phosphates, ideal for fine-grind mixing applications.

Key Features:

- Tangential acid introduction for cyclonic washing of the mixer cone

- Stainless steel or lead lined mild steel proprietary design mixing cone

- Overflow weir to prevent blockages and ensure complete wetting

- Customizable design with no moving parts

Drum Mixer

An improvement on the cone mixer, the drum mixer ensures complete mixing with variable residence time.

Key Features:

- Adjustable drum speed and inclination

- Suitable for high-grade phosphate applications

- No internal moving parts, ensuring minimal maintenance

- Requires constant operating conditions

Get the Right Mixer for Your Application

Bradley Pulverizer’s expertise in acidulation process mixing ensures that you get the best solution tailored to your process requirements. Contact us today for a consultation or to schedule laboratory testing to optimize your mixer selection.

- Video: Broadfield Process

- Article: Bradley Broadfield Superphosphate Process

- Article: The Importance of Phosphate Milling

- Article: Minimizing Heavy Metals in Superphosphate Manufacturing

- Article: Mill Optimizations for Low Grade Phosphate

- Brochure: Phosphate Processing with the Broadfield Process

- Brochure: Broadfield Process

- Infographic: Acidulation Applications for the Broadfield Processing System

- Timeline: 150 Years Servicing the Phosphate Industry