Grind, Classify, and Dry Material Simultaneously Utilizing Continuous Airflow

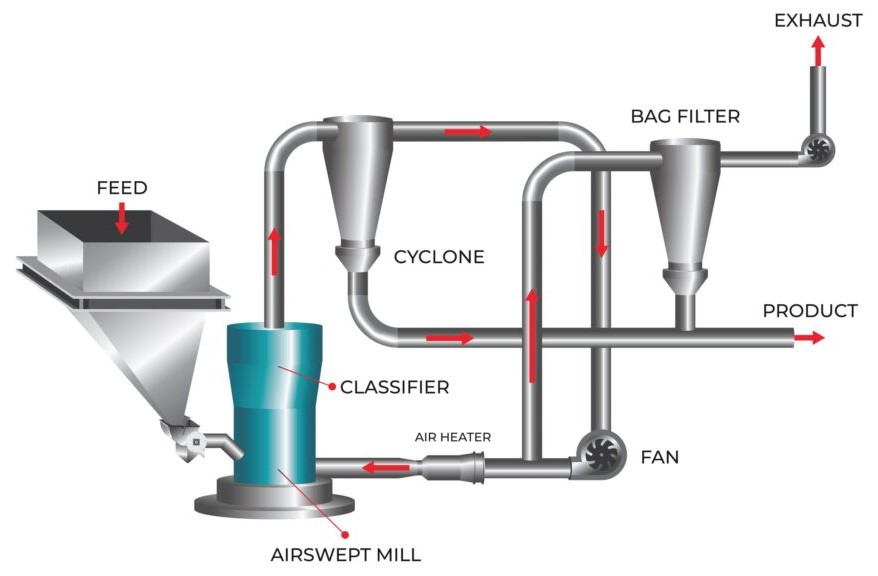

Recycled Air System

Most of the conveying air stream is recycled, with only a minimum amount being exhausted through the dust collector system, which is designed to remove the excess air and water vapor. This allows the system to operate under constant negative pressure, ensuring dust-free operation.

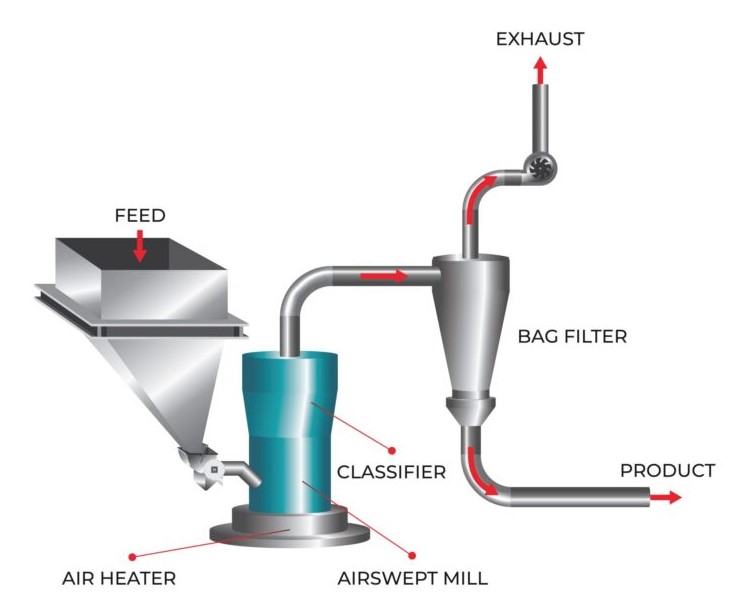

Single Pass Air System

With a single pass air system, air is drawn into the mill base, travels through the classifier, bag filter and fan and is then vented out to atmosphere.

In addition to being dust free, the air swept grinding zone prevents over-grinding by the air stream lifting the particles of certain sizes out of the grinding zone. The conveying air stream can also be heated to fluidize and dry material being ground.

Which System is the Right One for Your Application?

Whenever sourcing an airswept mill system, it is critical that both single-pass and recycled air systems be quoted

Learn More

Contact Us with your mill system requirements and we will make sure you get the right solution

- Which Airswept Mill is Right for Me: Single-Pass or Recycled System?

- Video: Airswept Mill Systems

- Case Study: Bradley Mill Overhaul and VBC Upgrade

- Article: The Importance of Phosphate Milling

- Article: Mill Optimizations for Low Grade Phosphate

- Brochure: Airswept Roller Mills

- Top Considerations When Selecting a Milling and Classification System

- Using a Divorced Classifier to Generate Multiple Products Simultaneously from an Airswept Mill System

- A Comparison of Mills Used for Phosphate Rock Grinding

- Mills for Phosphoric Acid Manufacturing