Blog-News

The Essentials of Phosphate Milling for Fertilizer Manufacturing

Part 1 of a 5-part blog series: “The Importance of Phosphate Milling”

Bradley Pulverizer’s Ian Hancock, VP of Sales & Operations, discusses the importance of a holistic understanding of the phosphate milling process to ensure maximum plant uptime, the highest process efficiencies and profitability. Click Here to download the complete article in pdf format as published by BCInsight Ltd in Fertilizer International July|August 2021, issue 503, pp. 49-52.

Grinding and pulverizing mills are the furthest upstream process in phosphate fertilizer manufacturing. The continuous crushing of phosphate rock to meet particle size specifications is essential for efficient downstream processing. Yet mills are more commonly seen as the ‘noisy neighbor’ to other process steps, rather than the essential engine that drives phosphates production. Regrettably, this lack of recognition for the importance of milling can cause inefficiencies upstream that are further compounded downstream.

Grinding and pulverizing mills are the furthest upstream process in phosphate fertilizer manufacturing. The continuous crushing of phosphate rock to meet particle size specifications is essential for efficient downstream processing. Yet mills are more commonly seen as the ‘noisy neighbor’ to other process steps, rather than the essential engine that drives phosphates production. Regrettably, this lack of recognition for the importance of milling can cause inefficiencies upstream that are further compounded downstream.

Phosphate rock is fed into the front-end of a production plant and manipulated many times during its long process journey and eventual transformation into valuable end-products. This continual production process is central to efficient phosphate fertilizer manufacturing, with each process stage requiring specialized equipment.

Join Bradley Pulverizer at the International Powder & Bulk Solids Conference & Exhibition

Be our guest….Bradley Pulverizer will be exhibiting at the Powder & Bulk Solids Conference & Exhibition, from August 24-26, 2021 at the Donald E. Stephens Convention Center in Chicago, IL and we’d love to meet you there!

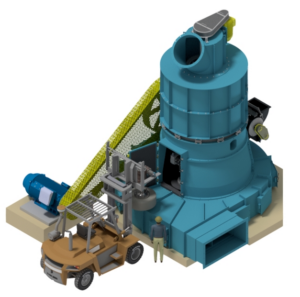

New Video Demonstrates the Over-Driven Design Advantages of Bradley Airswept Roller Mills

The Bradley Pulverizer Pendulum Airswept Mills have a unique over-driven design which provides several distinct advantages over the competition as demonstrated in this new video and table below. In particular, the integral gearbox located above the grinding chamber increases the mass of the mill resulting in less vibration in a quiet, low maintenance machine. Additionally, the ground level grinding chamber allows easy access to wear parts for safe and quick replacement.

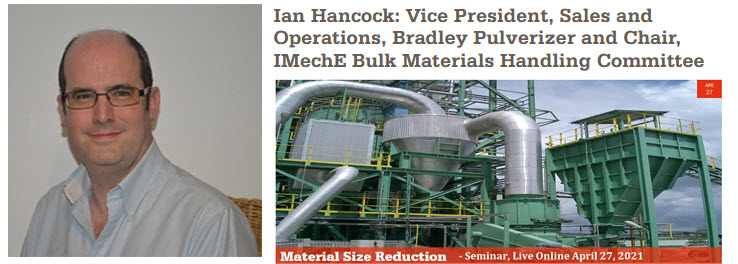

A Spotlight on Ian Hancock: Presenting “Fundamentals of Air Classification” at IMechE Live Online Seminar

We are excited for Bradley Pulverizer’s Vice President of Sales and Operations and Institute of Mechanical Engineers (IMechE) Chairman, Ian Hancock, to present Fundamentals of Air Classification at the Material Size Reduction live online seminar this April 27, 2021. Ian’s presentation will focus on 3 areas:

- The role of the classifier, different types, and their impact on classification efficiency

- Understanding the behavior of different materials to be sorted

- Basic understanding of cyclones and material separation post classifier

As a preview to the upcoming seminar, we thought it would be interesting to interview Ian and share his thoughts behind why he chose this topic and how it relates to the overall theme of Material Size Reduction.

As a preview to the upcoming seminar, we thought it would be interesting to interview Ian and share his thoughts behind why he chose this topic and how it relates to the overall theme of Material Size Reduction.

Performance Advantages of Bradley Mills

As discussed in our first blog of this series, Bradley Pulverizer is the only manufacturer of airswept roller mills designed with an overhead integral gearbox. This design allows for a spectrum of performance and cost saving benefits over other under-driven mills.

As discussed in our first blog of this series, Bradley Pulverizer is the only manufacturer of airswept roller mills designed with an overhead integral gearbox. This design allows for a spectrum of performance and cost saving benefits over other under-driven mills.

Performance Benefits:

- Less Vibration: The positioning of the integral gearbox above the grinding chamber adds 30% extra live mass to the mill increasing stability. A reduction in vibration also translates to less gearbox maintenance.

- Improved Efficiency: The spiral-bevel gears used in the Bradley gearbox, similar/identical to the gears used in helicopters, operate with higher efficiency than standard gearboxes used in under-driven mill. This means that almost 10% more of the absorbed power is available for grinding.

- Reduced Gear Wear: Higher efficiency means the Bradley mill gearbox oil does not need to be cooled, even when the mill is used with a dryer. This saves on installation and running costs.

- Optimization of Mill Speed with No Loss of Efficiency: The use of a V-belt drive allows full power of the motor at any speed, which is not possible with a direct drive and inverter which restricts mill capacity.

- Maximize mill Output: The V-belt drive also allows for mill speed to be increased so m output can be amplified without loss of efficiency.

Unique Design Advantages of Bradley Air Swept Roller Mills

Bradley Pulverizer has been a leading manufacturer of air swept roller mills for over 100 years. Our proven design provides efficient and reliable installations for the mineral industry worldwide. This blog is the first in a three-part series and discusses the key design advantages that contribute to the popularity and effectiveness of Bradley pendulum roller mills.

Integral Gearbox – Bradley mills are the ONLY mills with an integral gearbox on all of our models, including our large mills. Because the Bradley Mill gearbox is over-driven and sits above the grinding chamber, if offers several advantages over other under-driven mills.

Integral Gearbox – Bradley mills are the ONLY mills with an integral gearbox on all of our models, including our large mills. Because the Bradley Mill gearbox is over-driven and sits above the grinding chamber, if offers several advantages over other under-driven mills.

Integral Gearbox – Bradley mills are the ONLY mills with an integral gearbox on all of our models, including our large mills. Because the Bradley Mill gearbox is over-driven and sits above the grinding chamber, if offers several advantages over other under-driven mills.

- Spiral-Bevel Gears – The Bradley gearbox uses spiral-bevel gears that are so efficient, the gearbox oil does not need to be cooled, even when the mill system includes a dryer.

- Extra Live Mass: The over-driven gearbox adds 30% extra live mass to the mill, which results in less noise.

Press Release: Bradley Pulverizer Launches New Website

For Immediate Release – Allentown, Pennsylvania, December 16th, 2020 – Bradley Pulverizer is pleased to announce the launch of a newly redesigned website and social media presence. Since the acquisition of Bradley Pulverizer in January 2020, the company has developed a new digital strategy to support international operations and an expansion of its US sales force and engineering capabilities.

For Immediate Release – Allentown, Pennsylvania, December 16th, 2020 – Bradley Pulverizer is pleased to announce the launch of a newly redesigned website and social media presence. Since the acquisition of Bradley Pulverizer in January 2020, the company has developed a new digital strategy to support international operations and an expansion of its US sales force and engineering capabilities.

With over 130 years of serving the minerals industry, Bradley provides access to its deep technical and application expertise through its new digital offerings. As specialists in the design, manufacture, and commissioning of pulverizing and classifying systems, the company is committed to providing industry-relevant content easily accessible through its new website.

Which Airswept Mill is Right for Me: Single-Pass or Recycled System?

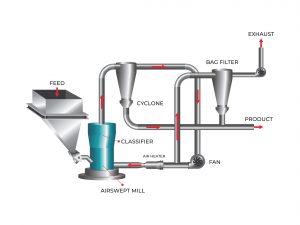

If you find yourself in the market as a first-time buyer of an airswept mill, or even if you’re an airswept mill ‘veteran’, chances are you will find yourself making the critical decision of choosing between a Single-Pass Airswept Mill System vs. a Recycled Air System. There are certainly projects where the specifications of the process dictate a clear-cut choice of one system over the other, but most fall into a gray area where the best solution can only be determined through a complete understanding of the process from raw material to end product.

Synergies Between Lancaster Products, Bradley Pulverizer, and Kercher Industries Lead to Improved Efficiencies and Market Growth

In January of 2020, Lancaster Products/Kercher Enterprises owner, Curt Snyder, acquired the assets of Bradley Pulverizer and we are thrilled to add over 130 more years of complementary industry experience to our 70+ years. While each will continue to operate as 3 separate businesses, we are already leveraging the benefits of the new acquisition. When Snyder first explored this opportunity he...

Press Release: Bradley Pulverizer Acquired By Lancaster Products Owner

For Immediate Release Contact: Curt Snyder 717-273-2111 [email protected] BRADLEY PULVERIZER ACQUIRED BY LANCASTER PRODUCTS OWNER Allentown, Pennsylvania, January 17th, 2020 – Bradley Pulverizer is pleased to announce new ownership. Lancaster Products & Kercher Enterprises’ owner Curt Snyder acquired the assets of Bradley Pulverizer through an affiliate effective on January 14th,...