High Efficiency Classification for Improved Particle Cut Size

Efficient classification involves accurately separating desired particle sizes from a moving airstream. The key to efficient separation is a design configuration where the forces acting on the particles are controlled in a continuous and uniform manner. For highest efficiency to be achieved, a very distinct relationship of velocities and forces needs to be maintained in the classifying zone.

Bradley Low Velocity Technology

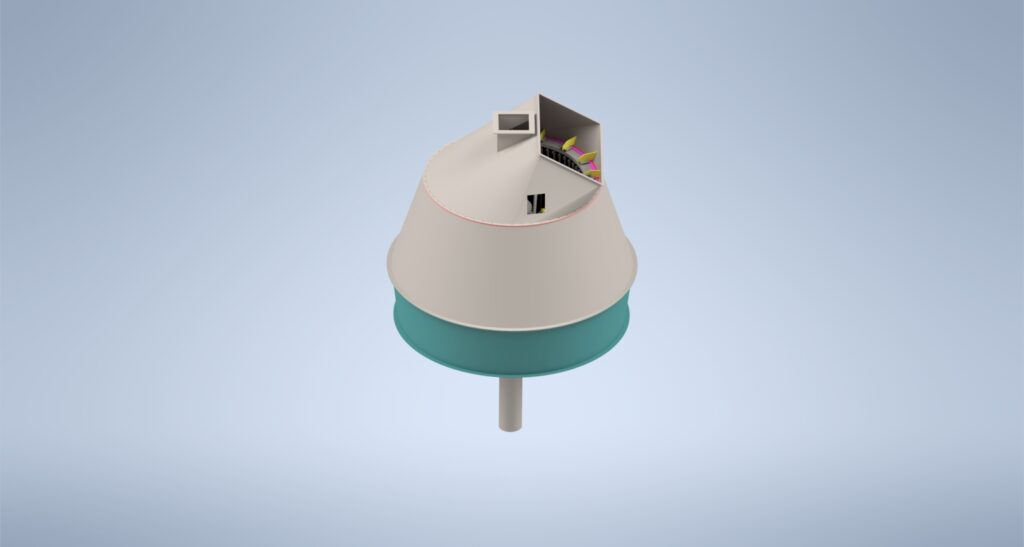

The Bradley Low Velocity Technology (BLVT) Classifier achieves high efficiency classification through our superior design. Because the BLVT classifier can be installed or retrofitted on any airswept mill, including pendulum roller mills, vertical roller mills and ball mills, it creates a quick payback period and high return on investment.

Increased mill capacity can be achieved by upgrading an existing classifier or replacing a current one with a high-efficiency classifier, such as the BLVT. Capacity improvements can be expected in the 15% to 17% range. The superior design provides controlled and guided material flow right up to and through the classifier. This results in improved particle cut-size and overall improved classification performance.

Additional benefits include reduced fan power and body wear due to the elimination of unnecessary re-circulation of material

BLVT Benefits

The BLVT Classifier offers additional benefits beyond those provided by other dynamic classifiers.

- Increased production capability or a finer grind capability

- Reduced system power consumption

- Reduced wear on mill body and components

- Reduced vibration for smooth system operation

- Easy to retrofit on existing mills

- High return on investment with short payback period

BLVT Classifier Concept

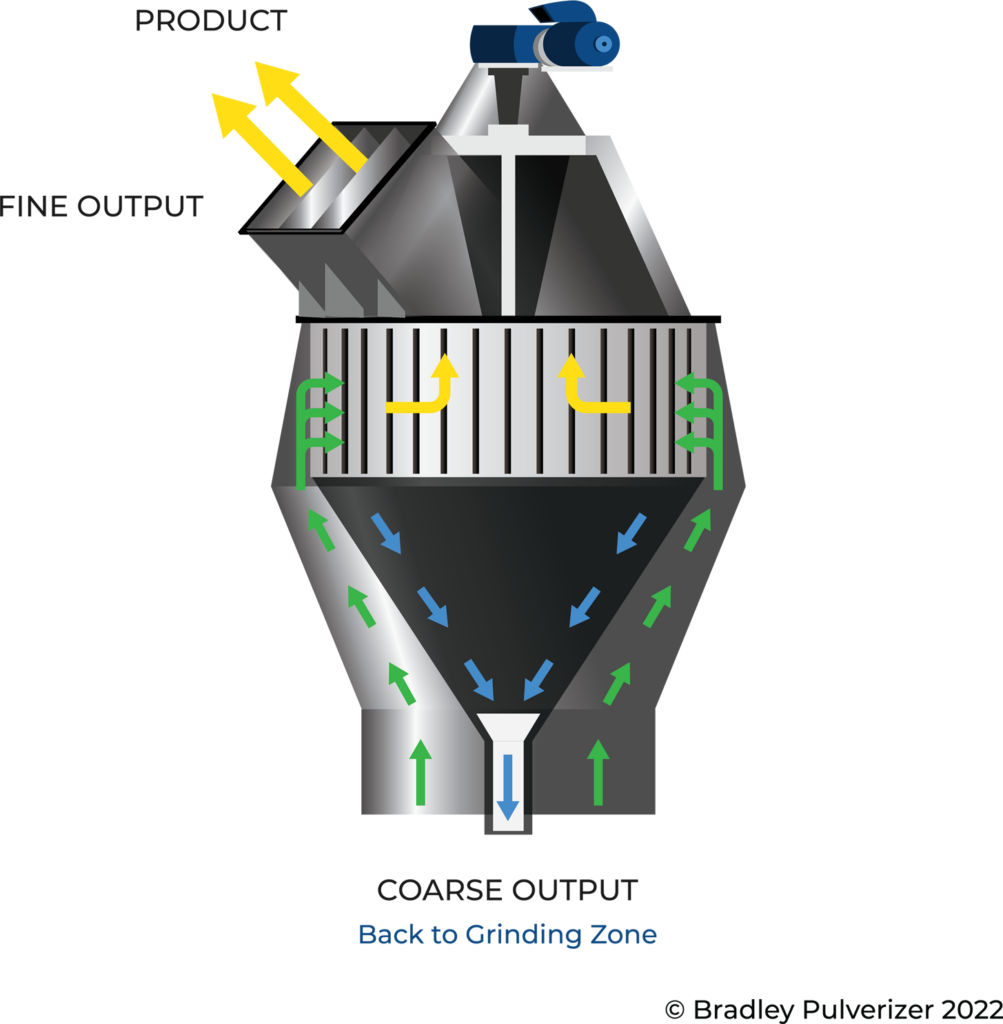

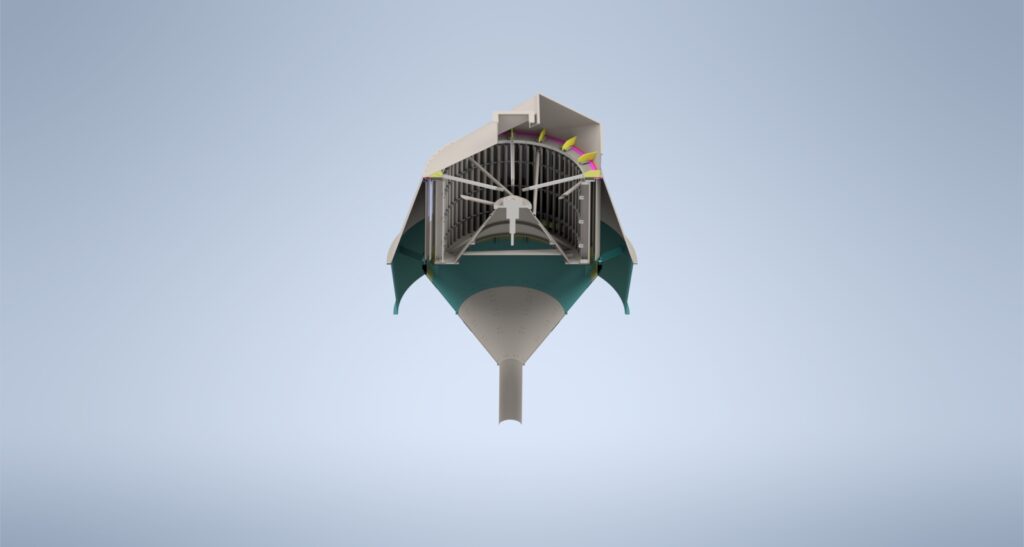

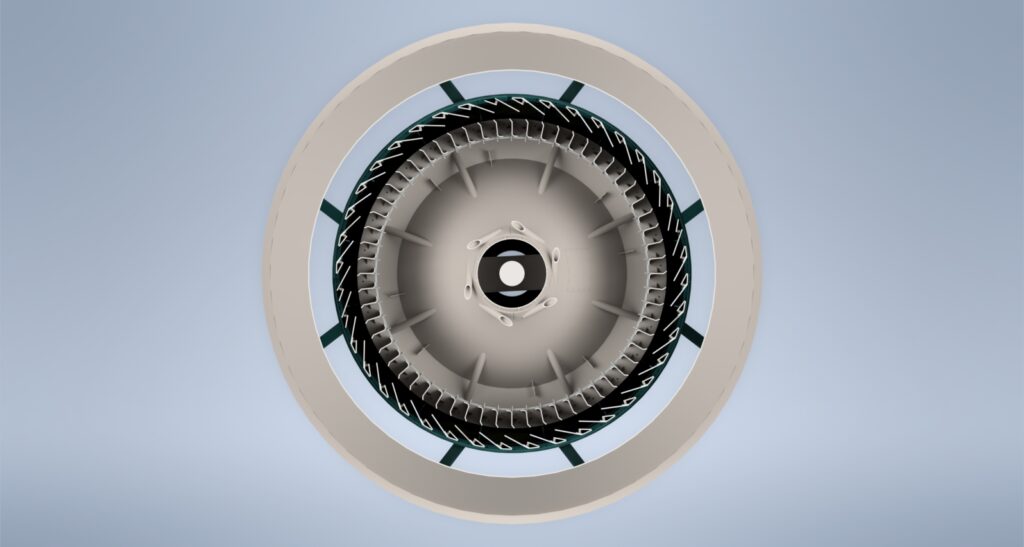

The BLVT Classifier is designed to optimize the air and material flow inside the mill and minimize unnecessary internal recirculation. This is accomplished by controlling the gas speed distribution of the classifier from material entry to exit.

Key Components:

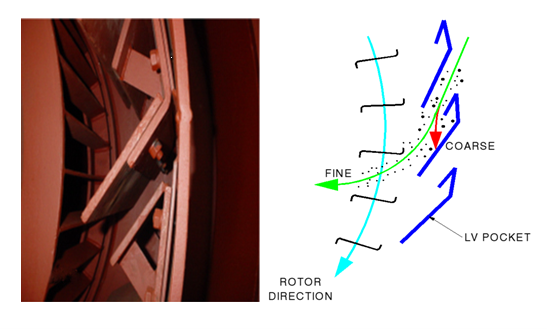

- LV Pocket Guide Vane – unique design allows coarse material particles to circulate back to the mill for re-grinding

- Rotor – accurately controls fineness setting by easily changing the rotor speed

- Grit Funnel – controls air and material velocity up to the classifier inlet and through the guide vanes assembly, into the classification zone and directs rejected material back to the mill

How It Works

The BLVT Classifier utilizes a turbine rotor surrounded by specialty pocket guide vanes and a classification zone. This design provides a two-layer classification system which first, rejects oversized particles with the pocket guide vanes then utilizes the separator rotor to further screen overly coarse particles.

The oversized coarse particles are carried by the airflow into the classifier where it impacts the angled pocket vanes, loses velocity and falls down into the grit funnel. This rejected material is directed down through the center of the grit funnel back to the grinding chamber, without passing through turbulent air-material currents.

The turbine rotor accurately controls material fineness setting by changing rotor speed. Target sized fine particles are carried out through the separator rotor and up to the cyclone or bag filter collector.

Contact Us to learn more about reliable air classification with efficient and economic operation

- Video: High-Efficiency BLVT Classifier

- Video: Airswept Mill Systems

- Article: Options for Improvement in Air Classification

- Case Study: Bradley Mill Overhaul and VBC Upgrade

- Brochure: BLVT Classifiers

- Brochure: Louvre Ring Retrofit

- Figure: Classifier Comparison Chart

- Ultrafine Air-Classification of Plant based Proteins: A Step Towards Reducing Carbon Footprints