Optimization of an airswept milling system for highest yields, efficiencies, and smooth operation can only be achieved when classifier technology is properly aligned with the specifications of the application. Bradley Pulverizer addresses the diverse needs of airswept milling systems by offering several different types of air classifiers, each implementing technology designed to achieve optimal particle classification for a given range of specifications. While some milling applications dictate a clear choice of particle classifier, in most cases, selecting the right air classifier involves considering the total cost of ownership, including overall yield rates and system profitability.

Bradley’s air classification solutions are versatile and compatible with mills from most OEMs including airswept mills, pendulum mills, ball mills, table and roller mills. Our classifiers can be seamlessly integrated with the mill with the added advantage of being retrofitted into existing systems.

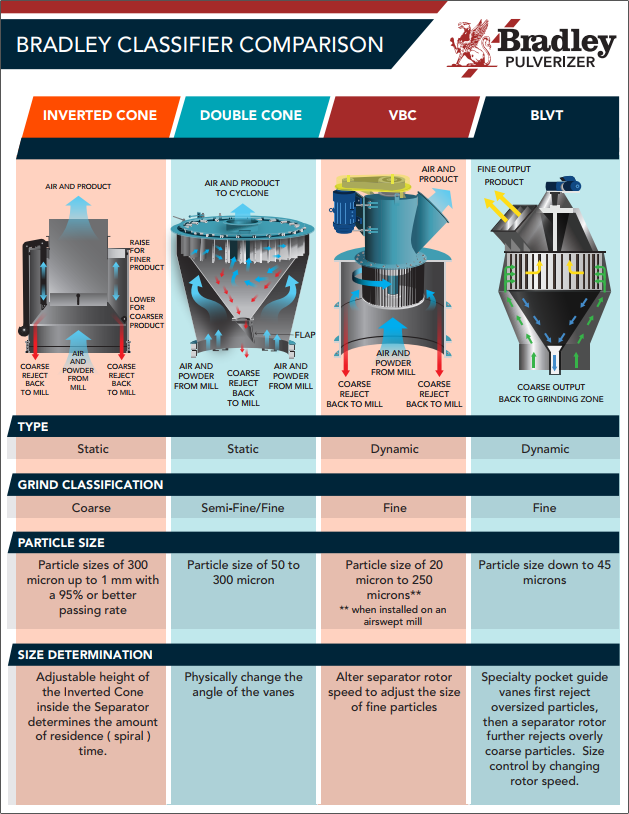

The wide range of options and overlapping performance specifications can make air classifier selection complex. To simplify this process and highlight the benefits of each classifier technology, we’ve developed a Classifier Comparison Chart featuring four key classifier technologies offered by Bradley Pulverizer: Inverted Cone, Double Cone, Vertical Blade (VBC), and Low Velocity Technology. This chart illustrates the primary operation method for each classifier and provides relevant information about grind classifications, particle size and size determination, typical applications, and more.

Contact Us if you are looking to improve classification efficiency, produce multiple products from one milling system, or working with abrasive materials or in harsh environments – Bradley Pulverizer has a classifier to meet your requirements.