For Improved Efficiency of Vertical Roller Mills

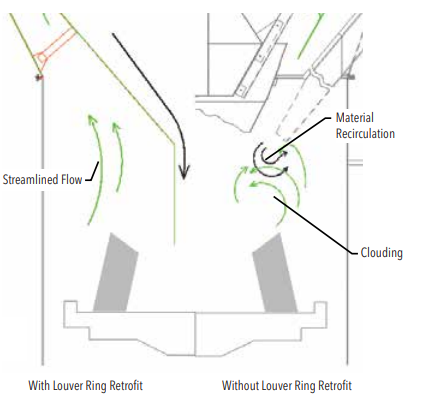

The design of the louver ring and armor ring plays a significant role in the performance of vertical roller mills. As the first classification stage takes place just above the louver ring, proper louver ring assembly should:

- Guide flow at upward incline with the armor ring

- Direct large particles back to the table

- Distribute flow evenly around the table

- Minimize the pressure drop

- Minimize high localized wear

- Manage the reject material stream

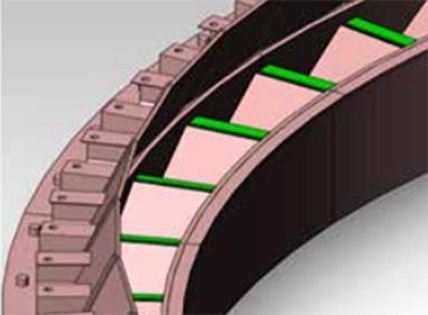

Bradley Louver Ring Retrofit Solution

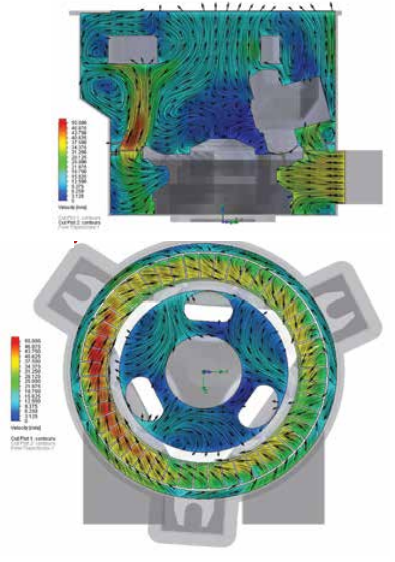

The Bradley Enhanced Louver Ring is designed for increased capacity and power reduction through improved grinding efficiency. To optimize results from a vertical roller mill, uniform gas flow distribution across the mill and classifier at any level is essential.

Conventional Louver Rings Vs. Bradley Enhanced Louver Rings

Conventional louver rings cannot equalize pressure and flow around the table. The unique Bradley Enhanced Louver Ring design regulates flow around the table to match the demands of the mill resulting in efficient operation and higher production rates.| Conventional | Bradley | |

|---|---|---|

| Wear on Mill Body & Internals | ||

| Internal Recirculation | ||

| Fan Drive Power | ||

| Operating Costs | ||

| Production Rate |

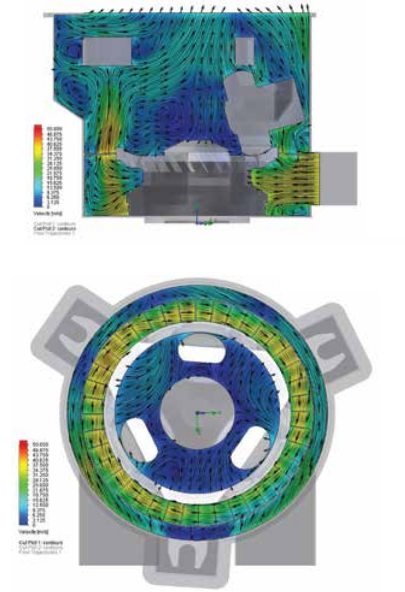

CFD Diagrams of Louver Ring Modifications

Call 855-670-8777 (International: +44 1322-559-106) or Contact Us to discuss ways we can optimize your vertical roller mill with a louver ring retrofit

Featured Resources